Looking at the bigger picture

Looking at the bigger picture

Laboratories, offices, clean rooms, exhibition space - that's 3,000 sqm at ZeMA. Since 2009, the Centre for Mechatronics and Automation Technology in Saarbrücken, Germany, has been working on transferring research and development results to industry as quickly as possible and implementing them in real applications. During our visit, Sophie Nalbach and Paul Motzki show us exactly what this looks like.

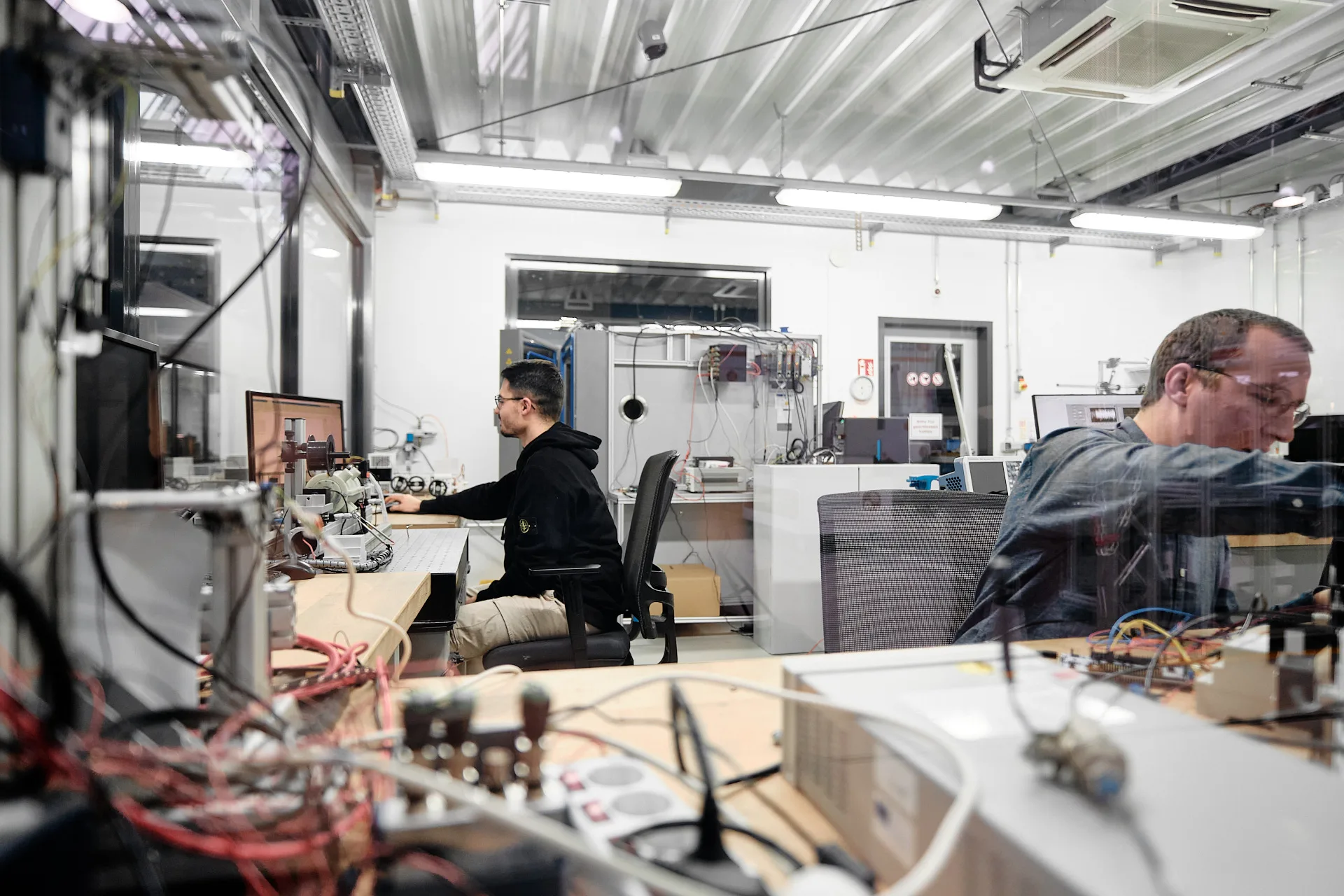

There is a lively and open working atmosphere at ZeMA: more than 120 employees work together in an interdisciplinary way, even across the six research areas. In addition to research and knowledge transfer, ZeMA promotes teaching activities and the training of engineers in close cooperation with the local universities. This brings together enormous scientific potential, specific expertise and the latest research findings. It is therefore only natural that ZeMA is often perceived and described by the public as the Saarland's think tank.

Linking industry and academia

Application-oriented research and industry-oriented development are part of ZeMA's self-image. Everything revolves around technology transfer to industry, which is achieved primarily through a strong network of more than 100 partners. The aim is to use new research findings to strengthen the Saarland as a knowledge and technology location on the one hand, and to generate new business models, new applications and new jobs on the other. But that's not all, the task is becoming more concrete - all developments should significantly increase energy efficiency and be climate-friendly.

In the laboratory, research results are developed and tested in an application-oriented and industry-oriented manner.

The interdisciplinary exchange between employees and research areas is highly valued at ZeMA.

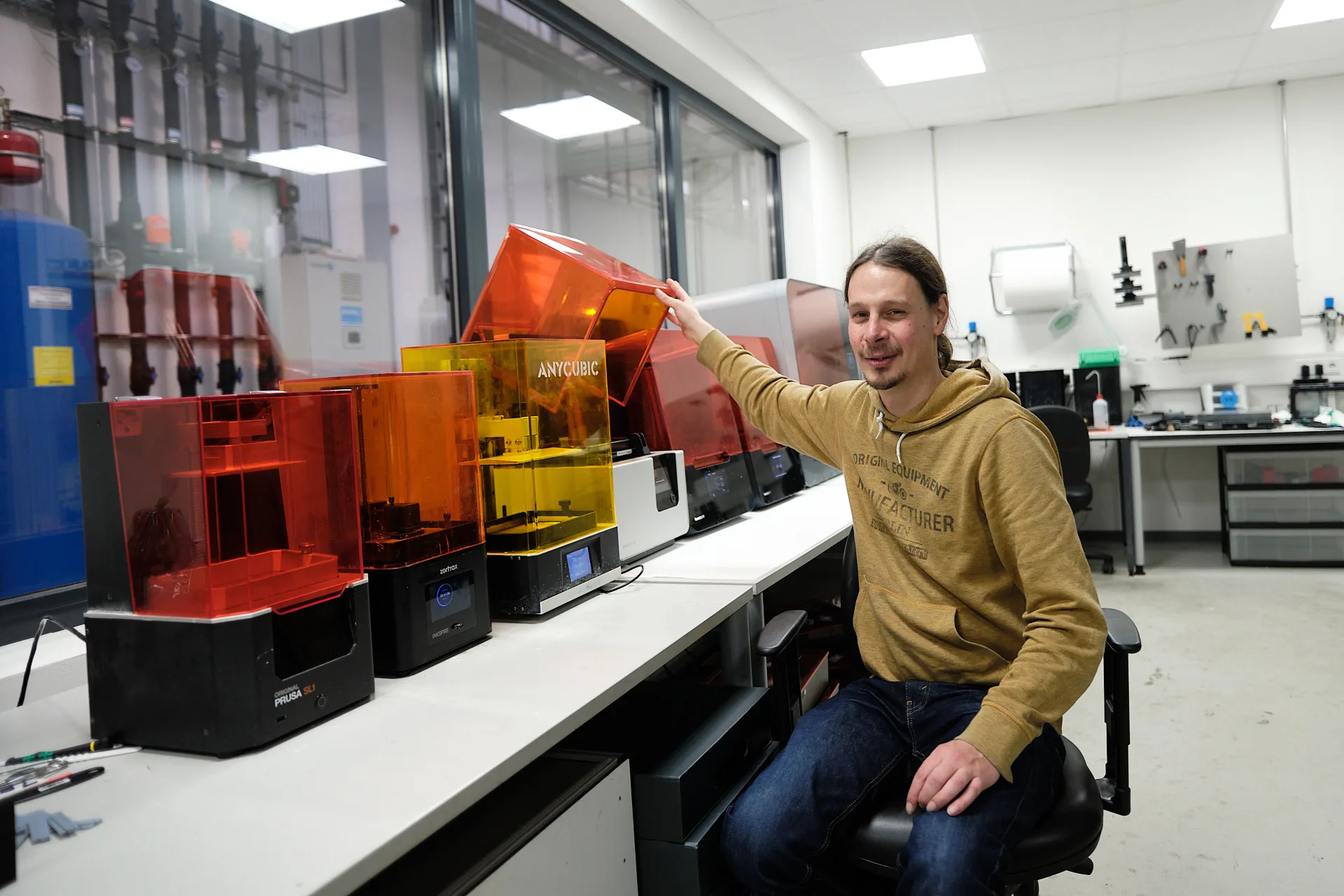

A diverse portfolio of 3D printing technology is available at ZeMA. Short paths and fast prototyping make agile research possible.

The iMSL – intelligent Material Systems Lab, which is both a research group at ZeMA and a chair at Saarland University, is eager to take on this challenge. Paul Motzki's SMiP professorship - Smart Material Systems for Innovative Production - also supports the development of mechatronic systems based on smart materials. There are many potential applications. The research results can lead to improvements in the automotive, aerospace, chemical, smart home and biomedical industries.

Building on what already exists

If you take a closer look at the collaboration at ZeMA and listen to Sophie Nalbach present the research projects, you will notice not only the uncomplicated "hands-on mentality", but also that the big picture is always taken into account. System solutions - it is precisely these that are thought up, tested and developed here. Research at the iMSL also draws on commercially available smart materials. Of course, why should a specific material, such as SMA wire, be developed further again and again when it is already fully developed and can be manufactured in series? Instead, the researchers at iMSL are interested in thinking ahead: they are looking at how the smart material can interact with all other components at least as intelligently and influence their interaction. As the name of the research group suggests, they are looking at the entire system.

Smart material systems with added value

However, Paul Motzki explains that there is still a long way to go before the research results can be transferred to industry, i.e. to future users, and to industrial production. A large part of the work at iMSL is therefore networking, communication, knowledge transfer and the presentation of research results. When visiting the ZeMA presentation hall and the "Smart Material Systems" area in particular, it becomes clear that the iMSL team is very good at this. The information boards and diverse demonstrators show the diversity of the research area, the proximity to industry and the enthusiasm for future topics.

And of course there are already research topics and applications that have made the leap.

Paul Motzki draws our attention to the startup mateligent which, together with its subsidiaries, has set itself the task of further developing the results of various research projects for industrial production and offering them on the open market. The aim is for smart materials to find their way into industry.

Exciting research projects that are currently being driven forward

Smart materials shape memory alloys are developed in "Bistable SMA Actuators" is responsible for switching between two positions with short activation pulses, which can be kept energy-free.

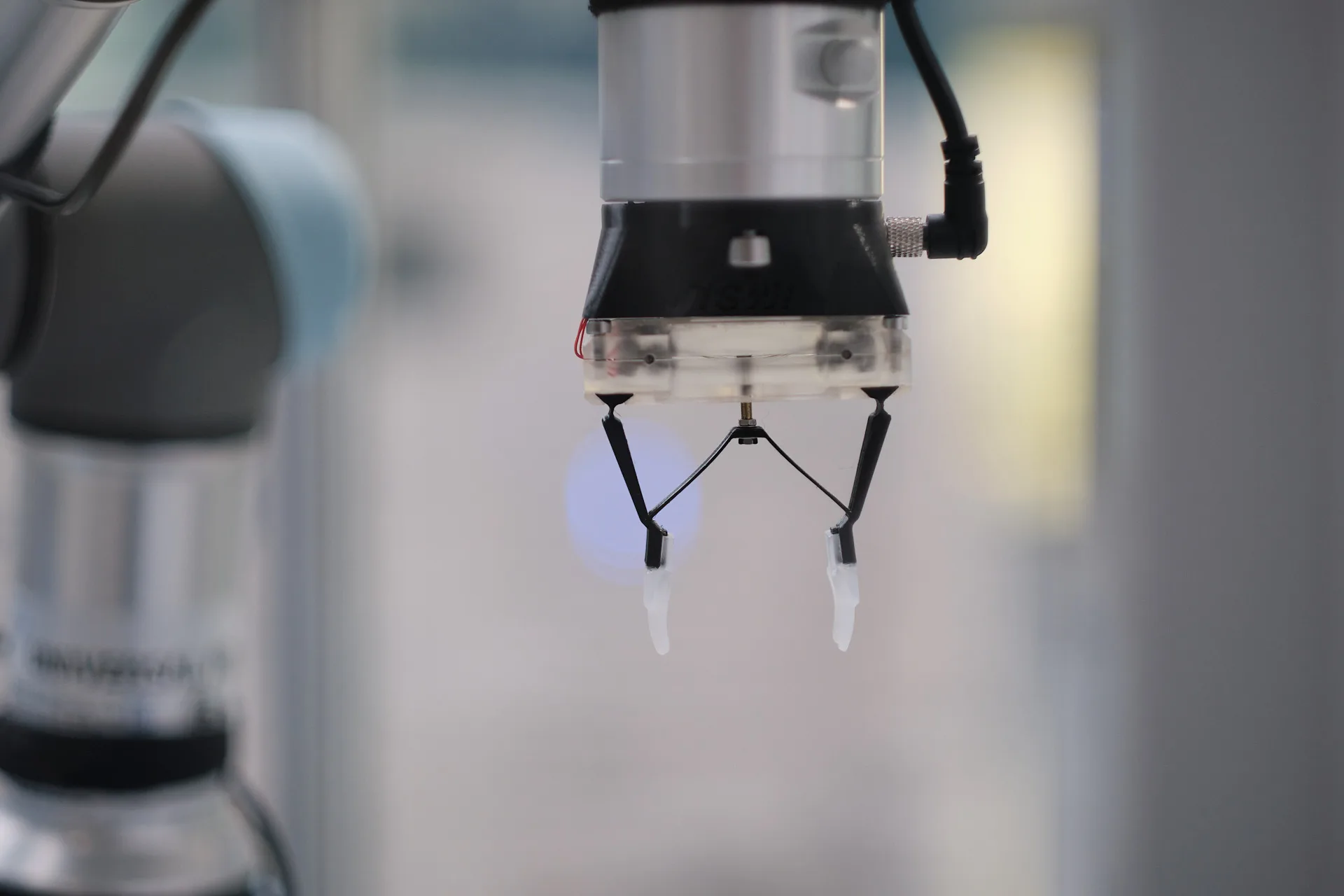

The same technology is also used in the "SMARTGrip" and installs the snap-action actuator ("Knackfrosch") from the project shown above. The resulting compressed air-free gripper technology with integrated sensors is fully electric, quiet, lightweight, highly efficient and suitable for cleanrooms.

Lightweight, variable in shape and energy-efficient - the "DE valve" is an electrically controlled valve based on an actuator made of dielectric elastomer according to the innovative "floating" concept.

The "Vibratory conveyor" uses dielectric elastomers as vibration actuators or vibratory conveyors to convey different granulates or goods in fine doses.

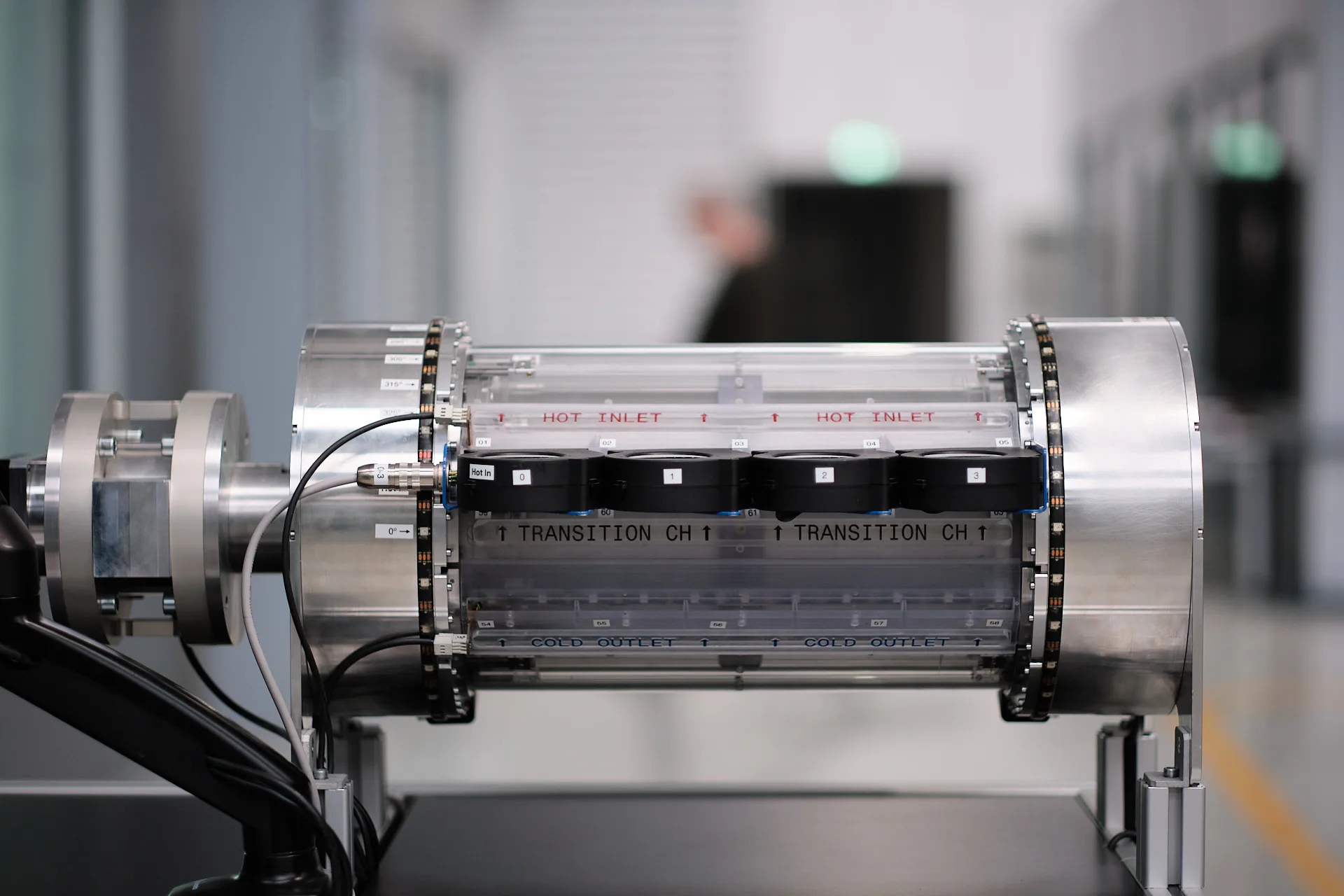

Currently on everyone's lips and celebrated as a topic of the future: Elastocaloric. No climate-damaging coolants and high efficiency: ZeMA has developed the world's first continuous air-to-air demonstrator to showcase the new technology.

The glove - equipped with sensor and actuator elements - can measure position, speed and force while being worn. At the same time, the user receives haptic, acoustic and/or visual feedback on certain activities.

But let's go back to the beginning: 3,000 sqm ZeMA is not just laboratories, offices, clean rooms and exhibition space. Above all, it's the variety of projects and what they all have in common: The agile way of thinking, the courage to try things out and the close collaboration of an interdisciplinary team. ZeMA and iMSL inspire and arouse curiosity for more, because what we remember most from our visit is that the goal of a research project here is not just a result, but rather an experience.

Prof. Dr.-Ing. Paul Motzki

- Director of the "Smart Material Systems" research area at ZeMA

- Professor of "SMiP - Smart Material Systems for Innovative Production" at Saarland University, Department of Systems Engineering

- Chairman of the VDI/VDE Technical Committee GMA 2.16: Smart Materials and Systems

Dr.-Ing. Sophie Nalbach

- Head of the "Smart Material Systems" department at ZeMA

- Managing Director at the professorship "SMiP - Smart Material Systems for Innovative Production" at Saarland University

Editorial team